NAVATA’s innovative products, designed to meet your application needs.

We design, build, and install high-performance heat exchange solutions across multiple industries, focusing on your specific design requirements.

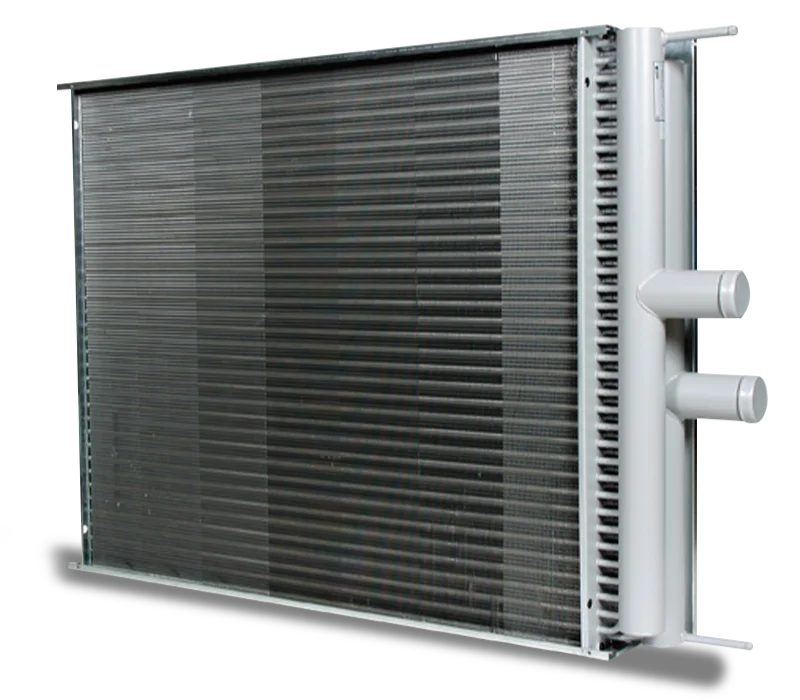

We have the capability to manufacture water coils in any size to meet your product application needs. Our software allows us to design systems for water, glycol, oil, or any other specialized fluid. Additionally, we are able to produce heat exchangers with a variety of tubing materials, including copper, copper-nickel, carbon steel, stainless steel, and many other custom materials. The standard connection will consist of headers made of carbon steel or non-ferrous metals, connected to pipes with threaded fittings, and will include vent and drain valves. Other connection types and fittings, such as flanges or Victaulic, are also available upon request.

We offer a variety of steam coils to meet your specific needs. Whether your application is for preheating air to the combustion chamber in a coal-fired power plant, drying grains before packaging, heating air in an air handling unit, or any other application, we have a solution for you. We can provide designs with either same-end or opposite-end connections. Our floating design helps prevent wear at the sheet metal fixing points caused by thermal expansion and contraction of the heat exchange tubes.

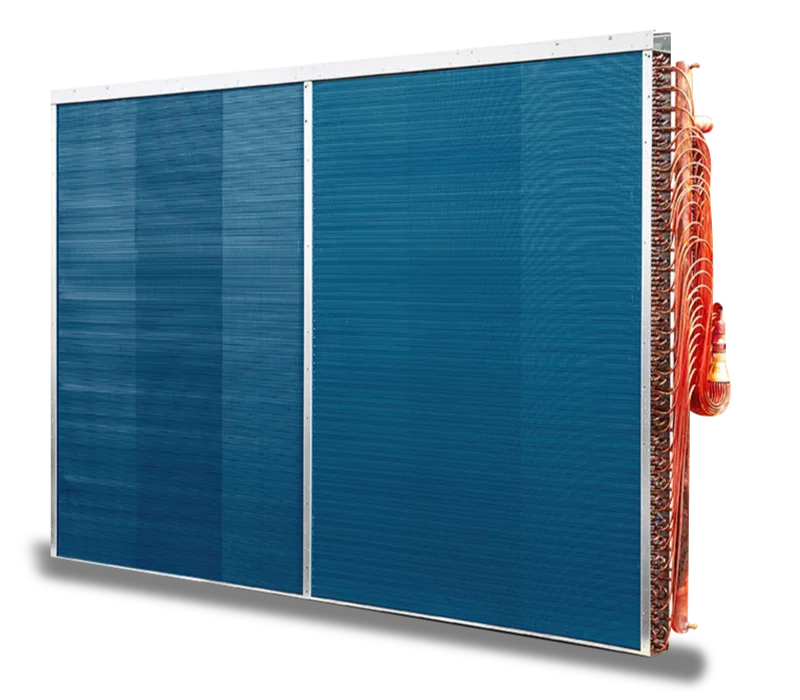

We design and manufacture a wide range of evaporator coils to meet your refrigeration needs. Each coil is custom-designed for your specific refrigerant and application, with various types available, including single and multiple circuit designs, such as face-controlled or staggered control. We offer stainless steel evaporators to suit different applications, such as high-corrosion environments and zinc-free copper applications in lithium battery workshops.

Each condenser coil is custom-designed for your specific refrigerant (including both traditional and new refrigerants) and application. We offer a variety of designs, including single-system and multi-system configurations, such as face-controlled or staggered control. Bent condenser coils and other custom designs are also available. Special fin materials and surface treatments enable the coils to be used in various environments with different atmospheric corrosion levels, while maintaining a long service life.